Max Capacity 2000kg/h 1500KG/H Extra Virgin Olive Oil Cold Press Machine By 2 Phase Centrifuge Extraction

Product Details:

| Place of Origin: | China |

| Brand Name: | Silk Road |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 set |

|---|---|

| Price: | $130,000.00 - $150,000.00/sets |

| Packaging Details: | All core equipment and spare parts are packed by exported standard wooden cases.<br>CPAO-1500 line can fit into 2*40ft container |

| Supply Ability: | 30 Set/Sets per Year |

|

Detail Information |

|||

| Applicable Industries: | Manufacturing Plant, Food & Beverage Factory, Farms, Olive Orchards | Max Capacity: | 2000kg/h |

|---|---|---|---|

| Showroom Location: | Italy, Peru, Mexico, Morocco | Condition: | New |

| Use: | OLIVE OIL | Type: | Centrifuge Extraction Machine |

| Automatic Grade: | Automatic | Production Capacity: | 1500KG/H |

| Voltage: | 220V/415V/440V | Dimension(L*W*H): | 19*8*6M |

| Weight: | 3500 KG, 3500KGS | Warranty: | 2 Years |

| Key Selling Points: | Long Service Life | Marketing Type: | New Product 2020 |

| Machinery Test Report: | Provided | Video Outgoing-inspection: | Provided |

| Warranty Of Core Components: | 2 Years | Core Components: | Motor, PLC, Bearing, Engine |

| Oil Type: | OLIVE OIL | Product Name: | Olive Oil Extraction Line |

| Extraction Method: | Centrifuge Extraction | Core Equipment: | Decanter And Separator |

| Equipment Material: | Stainless Steel 304 | Model: | EVOO-1500 |

| Capacity: | 1000-2000KG/H | Installation Power: | 80kw |

| Oil Yield: | 13.5% | Cover Space: | 19*8*6M |

| Port: | QINGDAO,SHANGHAI | ||

Product Description

Product Description

Olive Oil Cold Extraction Line EVOO-1500

EVOO series CENTRIFUGE EXTRACTION LINE is designed specially for EXTRA VIRGIN OLIVE OIL extraction from the ready paste by 2-phase or 3-phase separation(which is followed as per local government rules regarding the pollution issues).

Cold pressed extraction process could replace the traditional solvent extraction method to produce a virgin olive oil for the

edible oil market.

Generally,the whole system consists of the following 6 steps

1.- olive fruits reception and leaf removal system

2.- olive fruits washing system

3.- olive fruits crushing and paste malaxing system

4.- olive oil extraction system (2/3 phase optional)

5.- olive oil purification system

6.- olive oil storage and bottling system

All components such as decanter centrifuge and vertical separator are made in china!

Process Drawing

Process Description

Storage&Transfer Process

The collected fruits shall be put into small baskets first and delivered to factory,The baskets will stack in the ventilate storage warehouse to avoid oxidation&fermentation phenomenon because of the overheat and bruise.

Fruit Washing Process

The olive fruits are conveyed into the washing machine,then are rinsed and washed to remove the dust under the function of strong water flow.The water is collected for recovery by circulation tank under the vibration sieve.

Crushing Process

After crushing,the olive fruit pulp will be pumped into the malaxer for further process. The oil drops will be released and merge into large drops which can be separated easily by centrifuge.

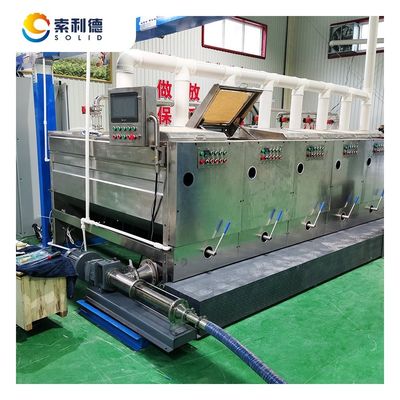

Pulp Malaxing Process

After crushing,the olive pulp will be pumped into the malaxer for further process. The oil drops will be released and merge into large drops which can be separated easily by centrifuge.

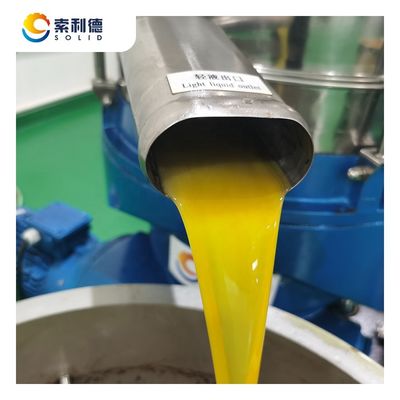

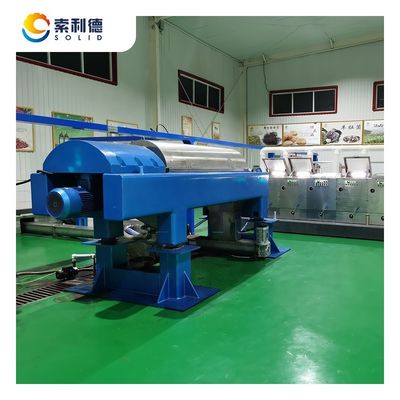

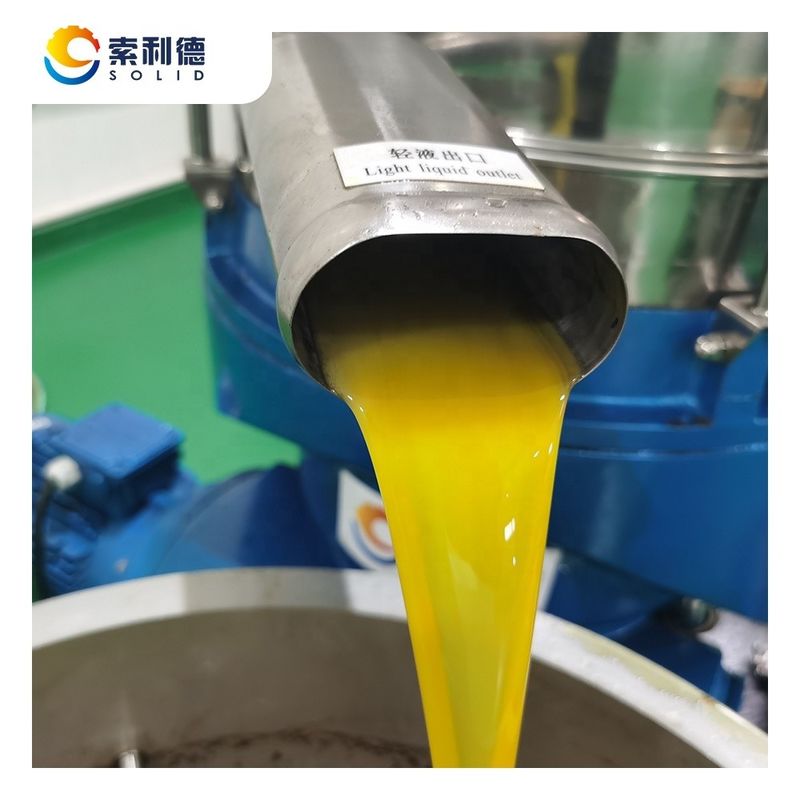

Centrifuge Extraction Process

After malaxing,the decanter centrifuge will be followd to separate the oil from pomace and water.During this process, 2 and 3 phase decanter centrifuge are available to meet production condition.

Oil Purification Process

After decanter,the oil still contains little moisure and impurities. Here a vertical disc separator is used to saparate the

impurities for final purified virgin olive oil.

impurities for final purified virgin olive oil.

Configuration List

S/N. | PROCESS EQUIPMENT | SPECIFICATION | POWER | QTY |

1 | WASHING MACHINE | FOOD GRADE SUS304 | / | 1 |

2 | CRUSHING MACHINE | FOOD GRADE SUS304 | / | 1 |

3 | PULP MALAXER TANK | FOOD GRADE SUS304 | / | 2 |

4 | DECANTER CENTRIFUGE | FOOD GRADE SUS304 | / | 1 |

5 | DISC SEPARATOR | FOOD GRADE SUS304 | / | 1 |

6 | CONTROL CABINET | CONTROL THE WHOLE LINE; CARBON STEEL | / | 1 |

Different Models for Choice

(The following capacity is based on the olive fruits input)

CPAO-500 | EV0O-1500 | EVOO-3500 | EVOO-5000 | EVOO-8000 |

10TPD | 30TPD-40TPD | 60TPD-80TPD | 100TPD-120TPD | 160TPD-180TPD |

Want to Know more details about this product